Holiday Inn Voltage Optimisation

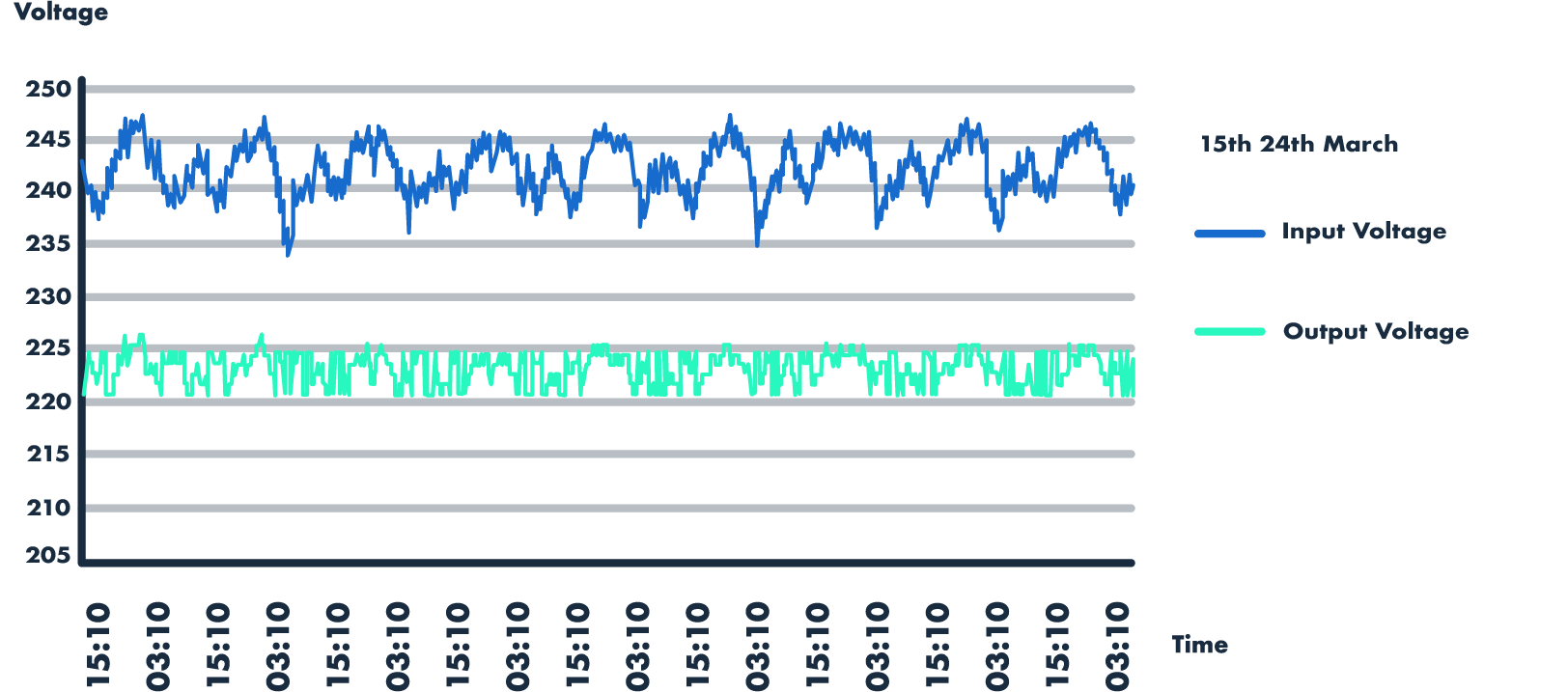

The graph above shows the optimiser provides a stabilised reduced voltage to the hotel, whilst ensuring it remains above 221v, and the integral power factor correction improves the power factor from 0.86 to 0.97.

The installation of the Staged Voltage Tracking Unit has mitigated the problems associated with large voltage fluctuations on site. Holiday Inn have seen a reduction in equipment failures, and associated replacement/maintenance costs as well as reduced electricity bills.

12.5% average energy savings achieved by the ECO-MAX, and savings of £5,837 per year, with a payback of 25 months

The Carbon Trust surveyed the hotel, with a view to identifying and prioritising up to 6 actions to reduce energy consumption. It was highlighted that voltage optimisation and power factor correction would be beneficial in reducing the hotels energy consumption.

GWE were contacted as a potential supplier, and it emerged that GWE were the only company that could supply a single solution to handle all of the specific site issues. Data logging allowed us to measure consumption and provide baseline figures. During this process it emerged that the site suffered from large voltage swings which made it unsuitable for standard forms of fixed voltage optimisation.

GWE’s EMPs optimisers are used to optimise the voltage to a single piece of equipment, localised area or an entire building. They can be supplied with fixed or variable outputs, with or without power factor correction.

In this instance a three stage optimiser with power factor correction was designed to deal with the specific issues identified, and to achieve the maximum possible energy saving. The unit was installed and further data logging carried out to measure the savings.