Kelloggs Voltage Optimisation

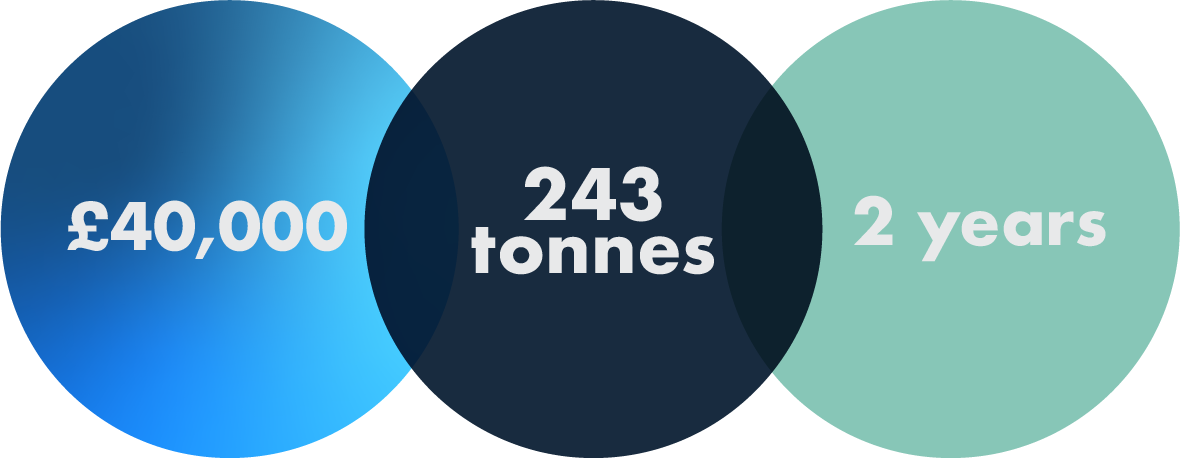

Savings per year.

Reduction in CO2 emissions

per year.

Project pay back.

Kelloggs have been working for years to continually improve their environmental performance, specifically looking at reducing their energy use, greenhouse gas emissions, water use and waste sent to landfill sites.

Part of this process involved surveying the facility, with a view to identifying actions to reduce energy consumption. It became clear that voltage optimisation would be beneficial in reducing the Manchester facility’s energy consumption and offer considerable cost savings too.

GWE were contacted as a potential supplier, and it emerged that GWE were the only company that could supply a single optimiser solution.

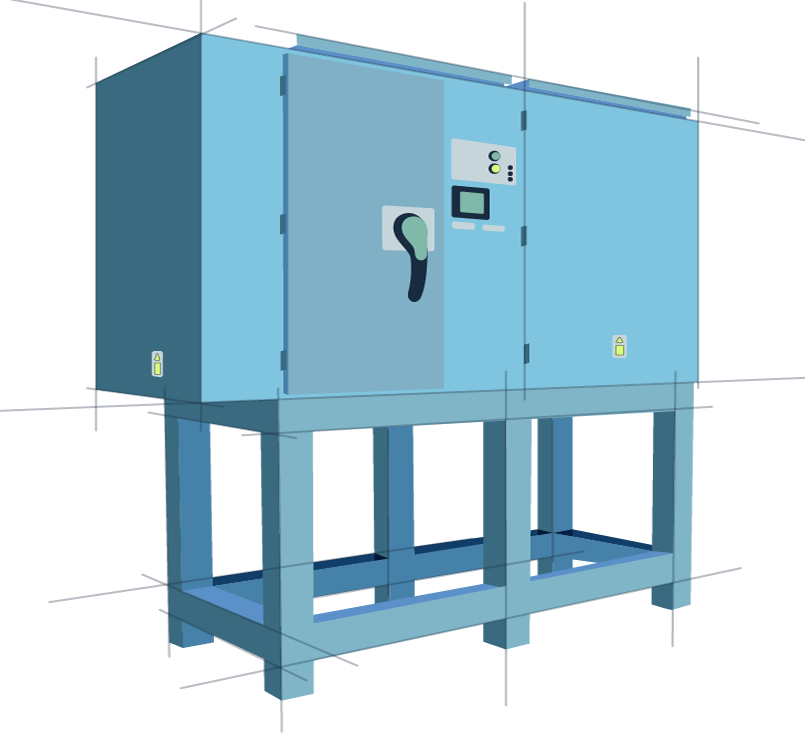

Data logging allowed us to measure consumption and provide baseline figures. During this process it became clear that the site suffered from large loading swings which made it unsuitable for standard forms of fixed voltage optimisation.

GWE’s EMPs optimisers are used to optimise the voltage to a single piece of equipment, localised area or an entire building. They can be supplied with fixed or variable outputs, with or without power factor correction.

In this instance a voltage tracking (stabilised) optimiser was designed to deal with the specific issues identified, and to achieve the maximum possible energy saving. The unit was installed and further data logging carried out to measure the savings.

Energy & Financial Summary of Project: